What is airtightness?

Here, I aim to give you a deeper understanding of what airtightness is, combining theory with the practicalities we’ve encountered working on the many low-energy retrofit and new build projects we’ve completed.

Chapter 1: Introduction, The Airtightness Imperative

In today’s age of sustainability, the topic of energy efficiency has steadily climbed the agenda of architects, builders, and homeowners alike. Notably, airtightness has emerged as a paramount concern, given its direct correlation with energy loss. Older homes, with their dated construction methods and less effective materials, have historically struggled with energy loss due to air leakage. However, as construction methods have modernised, the magnitude of the problem has only grown more apparent.

1.1 The Evolution of Housing and Energy Loss

To understand the significance of airtightness in contemporary construction, we must first look back. Historically, the construction of homes was more ‘breathable’, primarily due to the materials and techniques employed. These houses, while charming, often had gaps, cracks, and other points of air leakage. The result? Approximately 20% of energy, predominantly from space heating, would be lost due to these imperfections.

However, as society became more environmentally conscious, the methods of construction evolved. Modern homes became insulated havens with double or triple-glazed windows, improved wall insulation, and advanced heating systems. As these improvements reduced other methods of heat loss, the proportion of energy loss attributed to ventilation drastically increased. Today, it’s estimated that ventilation contributes to 35-40% of a home’s energy loss.

1.2 The Modern Paradigm

While our forebears might have been more accepting of a drafty home, modern homeowners are not. Rising energy costs, the push for green technologies, and the demand for energy-efficient homes have highlighted the importance of airtightness. It’s no longer sufficient to slap on a layer of insulation and call it a day. Every joint, seam, and intersection in a building needs scrutiny.

1.3 The Comprehensive Approach to Airtightness

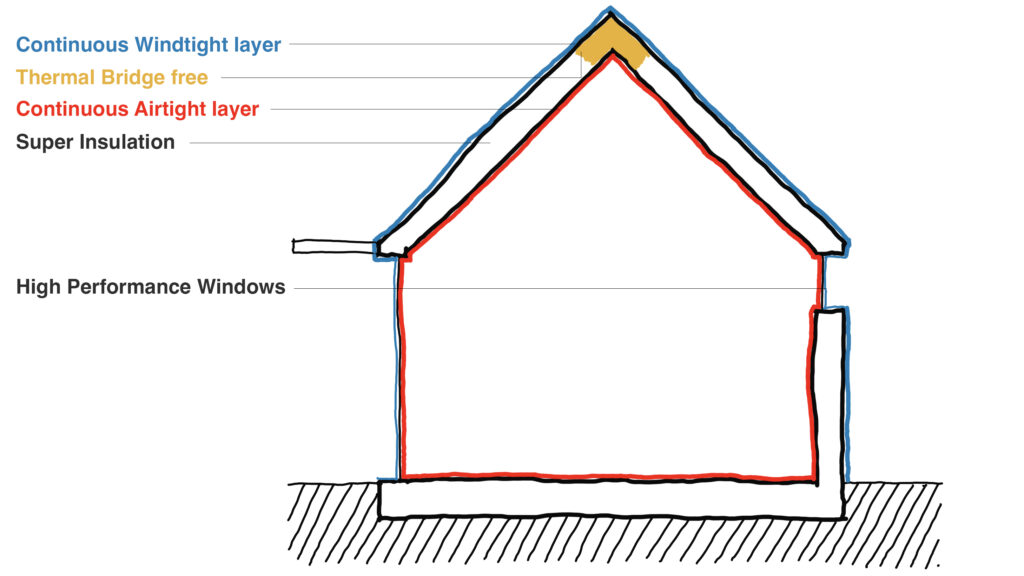

A comprehensive approach to airtightness doesn’t simply focus on sealing gaps. It requires a multi-faceted strategy that includes:

- Material Selection: Using advanced materials that inherently reduce air leakage.

- Construction Techniques: Employing methods that emphasise the airtight sealing of a building’s envelope.

- Mechanical Systems: Implementing controlled ventilation systems, ensuring fresh air intake without energy loss.

- Regular Maintenance and Checks: As buildings settle and age, potential problem areas might emerge. Routine checks ensure that a building remains as airtight as the day it was constructed.

In conclusion, as the architectural and construction industries continue to progress, the airtightness imperative will remain central to the dialogue. The benefits, ranging from reduced energy costs to a lower carbon footprint, make it clear that this is not just a trend but a necessary evolution in the way we build and inhabit spaces.

Chapter 2: What is Airtightness and Why is it Crucial?

The notion of airtightness might initially conjure images of sealed containers or vacuum chambers. However, when it comes to the built environment, this term carries a nuanced significance. Airtightness has come to the forefront of architectural discourse, not merely as a buzzword, but as an indispensable criterion for modern design.

2.1 Defining Airtightness

At its core, airtightness speaks to a building’s capacity to prevent unintended air exchange with its surroundings. This doesn’t mean a space void of fresh air, but rather, an environment where the inflow and outflow of air are meticulously controlled. This is measured in terms of air permeability, which quantifies the volume of air (in cubic metres) that leaks per hour through each square metre of the building’s external envelope under specific test conditions.

2.2 The Implications of Air Leakage

When a building is not airtight, it falls prey to the unpredictable whims of the environment. During colder months, warmth from the interior might escape, while in summer, the heat could intrude. This inconsistent interchange:

- Compromises Indoor Comfort: Rooms may feel draughty or have fluctuating temperatures.

- Increases Energy Consumption: As heating or cooling systems work overtime to compensate for the loss or gain of heat, energy usage escalates.

- Elevates Utility Costs: With energy consumption on the rise, utility bills can also see a noticeable uptick.

2.3 Airtightness: A Pillar of Modern Architecture

For an avant-garde design studio such as ours, the principles of airtightness are not just checkboxes in a compliance sheet. They represent the ethos of 21st-century architecture:

- Sustainability: With the global push towards eco-consciousness, reducing the carbon footprint of buildings has become paramount. Airtight buildings play a significant role in this pursuit.

- Innovation in Design: Modern architecture seeks not just to appease the eye but also to push the boundaries of what’s possible. Incorporating airtightness solutions challenges designers to innovate and redefine building norms.

- Holistic Building Performance: Contemporary design recognises that aesthetics and functionality are two sides of the same coin. Airtightness, thus, contributes to a building’s overall performance, enhancing occupants’ comfort and well-being.

2.4 Ensuring Airtightness: An Integral Phase

Ensuring a building is airtight is not an afterthought—it’s an intrinsic part of the design and construction process. This involves:

- Detailed Designing: Right from the drafting table, potential air leakage points are identified and mitigated.

- Material Specification: Using advanced membranes, sealants, and insulation which help in achieving the desired airtightness levels.

- On-site Verification: Employing tools like blower door tests to measure and verify the airtightness of a constructed space.

In summary, as the construction landscape evolves, understanding and emphasising airtightness remains pivotal. It is not just about conforming to standards but sculpting spaces that resonate with the needs and aspirations of our times.

Chapter 3: Modern vs. Older Homes: A Comparison

When delving into the domain of building construction and airtightness, it’s tempting to believe that advancements in technology and design inherently make modern homes superior to their older counterparts in every aspect. However, this isn’t always the case, especially when examining airtightness. Contrary to popular belief, some contemporary homes might fall short in this arena when compared to older structures.

3.1 The Architectural Evolution Over Time

The architectural journey, over decades, has been marked by evolving aesthetic preferences, changing materials, and innovations in construction techniques. Historically:

- Older Homes: They were often constructed with dense, solid materials, like brick and stone, which naturally provided a certain level of airtightness. The simpler design patterns, with fewer joints and breaks in the structure, minimised air leakage points. Ventilation was usually provided by natural draughts through less refined windows and doors.

- Modern Homes: These epitomise a blend of complex designs, large glazed areas, and a vast array of materials. While they offer numerous advantages, the complexity can introduce numerous potential points of air leakage if not meticulously managed.

3.2 The Paradox of Modern Construction

Modern buildings are not inherently flawed, but the challenges they pose in terms of airtightness include:

- Varied Workmanship: The quality of construction can fluctuate significantly due to diverse workmanship standards, potentially creating inconsistent airtightness levels across different buildings or even different parts of the same building.

- Complex Assemblies: Modern homes often feature intricate design elements—such as larger windows, complex junctions, and multiple material transitions—that can introduce vulnerabilities if not sealed appropriately.

- Rapid Construction: The drive to complete buildings quickly can sometimes lead to an oversight in ensuring airtightness.

3.3 Lessons from the Past

While older homes might lack many of the modern amenities and technological advancements, their approach to airtightness, albeit unintentional, offers lessons:

- Simplicity: Fewer joints and breaks mean fewer potential leak points. Modern designs can aim for a balance between aesthetic complexity and airtight simplicity.

- Use of Natural Materials: Traditional construction often leveraged materials that inherently provided good insulation and airtight properties. Revisiting some of these materials could be beneficial.

3.4 Striking the Right Balance

For the forward-thinking homeowner, architect or builder, the key lies not in choosing between old and new but in harmoniously blending the strengths of both:

- Informed Design Choices: Marrying the aesthetic appeal of modern designs with principles that enhance airtightness.

- Quality Control: Ensuring that the workmanship standards are consistently high across all stages of construction.

- Continuous Innovation: Integrating new technologies and materials that offer better airtightness solutions without compromising on design.

In conclusion, while the dichotomy between modern and older homes presents unique challenges, it also provides a rich tapestry of insights. Embracing the best of both worlds can lead to spaces that are not only visually compelling but also functionally superior in terms of airtightness.

Chapter 4: Current Standards and Achievements

The realm of building and construction, particularly when it comes to airtightness, is a dynamic field. Regulations and standards are set to maintain a certain quality level and ensure energy efficiency. Yet, as the industry evolves, so does the challenge of consistently meeting these established standards. The Building Regulations 2022 is a testament to such an ambition, but how does it fare in practical scenarios?

4.1 An Overview of Building Regulations 2022

The Building Regulations 2022 is a cornerstone for construction standards in the UK:

- Airtightness Standard: One of its regulations is the airtightness of buildings, setting the bar at 10 m3/hr/m2. This benchmark is founded on the principles of energy conservation, comfort, and sustainability.

- Part L1A of the Building Regulations stipulates the baseline requirements for testing at a threshold value of 10m³/hr/m². However, the rate often required to achieve the TER is considerably lower.

- In most designs, values ranging from 4 to 6m³/hr/m² are utilised. With meticulous attention to the details during the construction phase, these rates can be easily met. Once the construction is finalised, the actual air leakage rate is ascertained through on-site testing.

- High-performance constructions, like Passivhaus homes, often consistently record rates lower than 1m³/hr/m².

- All new homes must undergo testing upon completion, with two specific exceptions: 01: If an identical construction has been completed by the same builder within the previous year and has satisfactorily passed an airtightness test. 02: When a high default value of 15m³/hr/m² is applied in the SAP assessment.

- If you wish to circumvent the uncertainty of on-site testing, an air leakage rate of 15 can be selected. This rate is akin to having a sizeable window left open during the test, thus eliminating the need for testing entirely. However, this would necessitate substantial countermeasures like extra-thick insulation amongst others.

4.2 Dissecting the Survey Findings

A survey targeting 100 contemporary homes brought some revealing insights:

- Startling Figures: While standards project a certain level of airtightness, approximately 33% of these homes didn’t even achieve the set benchmark. Such a deviation is a cause for concern, indicating a potential disconnect between regulatory standards and on-ground execution.

- Variability in Construction: Even within modern constructions, there was a vast variance in airtightness levels. While some exceeded the standards, others lagged woefully behind.

4.3 Impediments to Achieving the Standard

Several factors contribute to this noticeable disparity:

- Knowledge Gap: Not all builders and contractors might be fully versed in the nuances of the airtightness standards, leading to unintentional oversights during construction.

- Workmanship Consistency: As previously discussed, variability in workmanship quality can result in different airtightness levels.

- Cost Factors: Achieving high levels of airtightness might involve additional costs in terms of materials and labour. Some builders might cut corners to stay within budgets.

- The Complexity of Modern Designs: Advanced architectural designs can inadvertently introduce challenges in maintaining airtightness.

4.4 The Way Forward: Bridging the Gap

While the current scenario isn’t entirely bleak, there’s an evident need for course correction:

- Awareness Campaigns: Construction industry stakeholders, including architects and builders, need periodic updates and training on the importance and techniques of achieving airtightness.

- Robust Inspection Mechanisms: Regular and rigorous inspections during and after construction can help identify potential lapses and rectify them timely.

- Feedback Loops: Learning from projects that failed to meet the standards can provide invaluable insights for future constructions.

- Rethinking Standards: It might be beneficial to revisit the standards themselves periodically, ensuring they are in sync with current technologies, materials, and construction practices.

In summation, while standards like the Building Regulations 2022 provide a fairly solid foundation (but does need to be improved considerably due MVHR only being efficient when airtightness is below 7 m3/hr/m2), their real-world implementation demands continuous monitoring and adaptation. Only through concerted efforts from all industry stakeholders can the aspiration of optimal airtightness in every home be achieved and improved.

Chapter 5: Key Areas of Concern: Common Air Leakage Points

When aiming for optimal airtightness in buildings, it’s crucial to identify and address potential weak points where air leakages might occur. These weak points, often arising from various construction phases or oversight, can significantly compromise the energy efficiency of a structure. Our on-site experiences have illuminated some of the most recurrent areas of concern.

5.1 Gaps around Window Frames, Doors, and Floor Joists

- The Issue: Improper sealing or alignment of windows and doors often leads to discernible gaps, while floor joists can sometimes be overlooked in terms of insulation and sealing.

- The Solution: Utilising high-quality sealants, ensuring precise fittings, and opting for insulated frames can effectively mitigate these issues. Further, insulation between floor joists can restrict air flow and enhance thermal efficiency.

5.2 Hollow Sections in Suspended Floors or Walls

- The Issue: These sections can act as conduits for unwanted airflow due to cavities created during construction or as a design feature.

- The Solution: Proper insulation within these hollow sections or using solid construction techniques can reduce or eliminate such air pathways.

5.3 Cracks in Masonry or Gaps Behind Plasterboards

- The Issue: Natural settling of buildings or subpar masonry can result in cracks. Similarly, improperly installed plasterboards can leave air pockets.

- The Solution: Regular building inspections can help identify these issues early on. Filling cracks with appropriate sealants or mortar and ensuring flush plasterboard installations can address these concerns.

5.4 Areas Around Pipes, Vents, Heating Systems, and Electrical Fixtures

- The Issue: These installations often require openings in walls, floors, or ceilings. If not sealed correctly, they can become significant sources of air leakages.

- The Solution: Using gaskets, sealants, or specially designed collars around these installations can ensure a tight fit and minimise air infiltration.

5.5 The Imperative of Meticulous Inspection

Ensuring airtightness is not merely about addressing the obvious points of leakage but also about conducting thorough and regular inspections:

- Proactive Identification: Regular inspections, especially post-construction and during maintenance phases, can spot potential problem areas before they escalate.

- Leveraging Technology: Tools like thermal imaging cameras can visually pinpoint areas of air leakage, making the task of sealing and repair more targeted.

- Skilled Professionals: Engaging professionals with expertise in building diagnostics can lead to more accurate identification of leakage points and suitable solutions.

In summary, while contemporary construction offers numerous advantages, it also brings its own set of challenges. By understanding and addressing common air leakage points, we can significantly improve the energy efficiency and comfort levels of a building. Meticulous inspection, combined with preventive and corrective measures, ensures that our structures stand the test of time and utility.

Chapter 6: The Airtightness Barrier: An Architect’s Tool

The airtightness barrier often likened to an invisible shield, plays a pivotal role in modern architectural design. Its essence lies in ensuring that a structure remains as impervious to unwanted air infiltration and exfiltration as possible, preserving energy efficiency and promoting a comfortable interior environment. But what is this barrier, and how can architects integrate it seamlessly into their designs?

6.1 Understanding the Airtightness Barrier

- Definition: The airtightness barrier isn’t just a single layer or component. Instead, it’s a holistic system, encompassing a variety of materials and techniques, all working in unison to prevent unwanted airflow. This might include membranes, tapes, sealants, and gaskets.

- Functionality: Beyond just preventing air leakage, this barrier also ensures the controlled exchange of air. This means that while uncontrolled air leakage is minimised, ventilation systems can operate more efficiently, ensuring good indoor air quality.

6.2 Integration at the Design Stage

- Holistic Approach: Rather than being an afterthought, the airtightness barrier must be integrated right from the conceptual stage of design. This ensures that the barrier complements structural and aesthetic elements rather than hindering them.

- Flexible Solutions: Depending on the building type, purpose, and location, the specifics of the barrier can vary. Thus, architects need to tailor the barrier to each project’s unique needs.

6.3 Key Considerations for Architects

- Material Selection: Architects should opt for durable and resilient materials for the barrier, considering the local climate, potential exposure conditions, and desired lifespan of the structure.

- Seamless Transitions: Where different materials or building components meet, there’s a heightened risk for air leakage. Architects should design in such a way that these transitions are meticulously sealed and guarded against potential breakages.

- Incorporating Ventilation: While the objective is to minimise uncontrolled air leakage, architects must also plan for controlled ventilation, like Mechanical Ventilation Heat Recovery (MVHR). This ensures fresh air exchange without compromising the efficiency of the barrier.

6.4 Future Innovations and Adaptations

- Technology-Driven Solutions: As building technology evolves, architects can leverage advanced tools and software to simulate and test the efficacy of their airtightness barrier designs.

- Continuous Learning and Upgradation: The world of architecture is in perpetual evolution. By staying attuned to emerging best practices and novel materials, architects can continually refine their approach to airtightness.

In conclusion, the airtightness barrier is an indispensable tool in the architect’s arsenal. It not only upholds the energy efficiency and comfort of a building but also accentuates the importance of forward-thinking, sustainable design. By weaving this barrier seamlessly into the fabric of their designs, architects are able to create structures that stand as testimonies to both form and function.

Chapter 7: Developing an Airtightness Strategy: From the Drawing Board to the Site

The art of crafting a building that stands against the onslaught of uncontrolled airflow is no mean feat. An airtight building is not just about integrating specific materials but encapsulating a vision that spans from initial sketches to the very last brick. The journey is intricate, demanding a blend of foresight, strategy, and concerted teamwork.

7.1 Setting Clear Performance Targets

- Benchmarks and Metrics: Every successful airtightness strategy commences with well-defined targets. By stipulating specific air leakage rates or other measurable benchmarks, the project sets clear expectations from the outset.

- Adherence to Regulations: While setting targets, it’s imperative to align with existing building regulations and guidelines, ensuring that the building not only meets but exceeds industry standards.

7.2 Leveraging Performance-based Specifications

- Material and Component Selection: Using performance-based specifications means that materials and components are chosen based on their ability to meet the desired performance criteria, rather than just their inherent characteristics.

- Continuous Assessment: Regular performance evaluations during construction ensure that the project remains on track and that any discrepancies can be addressed promptly.

7.3 Ensuring Stakeholder Alignment

- Workshops and Training: It’s pivotal that everyone involved, from masons to electricians, is on the same page. Hosting workshops or training sessions can help familiarising teams with the airtightness strategy.

- Regular Communication: Open lines of communication between teams can facilitate the identification and resolution of potential airtightness challenges. Frequent meetings, updates, and feedback sessions can prove beneficial.

7.4 The Role of the ‘Airtightness Champion’

- Duties and Responsibilities: The Airtightness Champion is not just a title. This person is tasked with overseeing the entirety of the airtightness strategy, from monitoring material procurement to ensuring quality control on-site.

- Bridging the Design-Construction Gap: One of the pivotal roles of the Airtightness Champion is to ensure a seamless transition of the airtightness vision from design to construction, eliminating ambiguities or misinterpretations.

- Advocacy and Awareness: This champion also plays an educational role, advocating for best practices, introducing new techniques, and ensuring all members understand the importance of airtightness.

7.5 Iterative Refinement and Feedback

- Post-Construction Analysis: Once a project is completed, a thorough analysis can provide insights into what worked and areas of improvement. This feedback can then inform future projects.

- Incorporating Technological Tools: Tools such as blower door tests or thermal imaging can offer real-time data during construction, facilitating adjustments in the airtightness strategy as needed.

In summary, creating an airtight building is a symphony of precise strategy, unwavering focus, and harmonious teamwork. It’s about setting clear visions, arming oneself with the right tools, and ensuring every hand that touches the project does so with airtightness in mind. With such a holistic approach, the resulting structures not only stand firm against air leakages but also serve as benchmarks for others to emulate.

Chapter 8: Practical Steps to Achieving Airtightness

Airtightness is as much about tangible measures as it is about theory. Successful integration of airtightness in a building requires attention to detail, a deep understanding of materials, and rigorous processes. Here, we delve into some of the hands-on steps we’ve employed to translate our airtightness strategy into concrete outcomes.

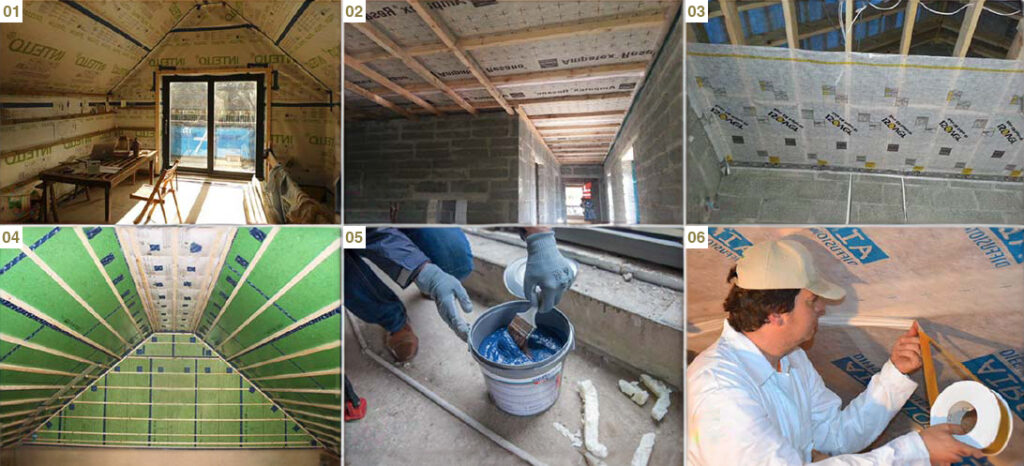

8.1 The Imperative of Air Barriers

- Characteristics of Ideal Barriers: The crux of airtightness lies in choosing barriers that are impermeable to airflow, continuous across junctions, and durable over time. Whether it’s a vapour barrier or a more rigid material, ensuring its continuity is essential to prevent leakages.

- Positioning and Installation: Air barriers must be placed in areas where they won’t be compromised by subsequent building processes or later modifications.

8.2 Sealing Laps in Membranes

- Material Selection: Specialised tapes and adhesives are imperative for ensuring the tightness of joins in air barrier membranes. Opting for high-quality materials that adhere well and remain effective over time is vital.

- Technique: Correct lapping, typically overlapping the upper layer over the lower one, ensures that any water moving downwards doesn’t penetrate the barrier.

8.3 Window, Door, and Fixture Sealing

- High-Quality Sealants: Using premium-grade sealants, which offer long-lasting protection against the elements, is paramount.

- Attention to Detail: This involves not just the external perimeter but also areas like window and door sills, which can often be overlooked. Ensuring full perimeter sealing can drastically reduce air leakage.

- Insulation: Beyond sealing, effective insulation of these openings, using products like expanding foam, can further enhance airtightness, but care must be taken when using expanding foam as studies have found that the foam can degrade over time creating air leakages.

8.4 Addressing Services in External Walls and Floors

- Seal Service Penetrations: All service conduits, whether for electricity, water, or gas, must be meticulously sealed at the point they penetrate external barriers. This can be achieved using collars, grommets, or specific sealants.

- Regular Inspection: Over time, seals can degrade or become compromised. Regular inspections can ensure any wear and tear is promptly addressed.

8.5 Airtight Light Fittings and Redundancy Measures

- Lighting Considerations: Opting for airtight light fixtures ensures that the integrity of ceilings isn’t compromised. Where traditional fittings are used, additional sealing measures might be needed.

- Unused Areas: Features like unused fireplaces can become significant sources of air leakage. Installing chimney balloons or draught-proofing measures can effectively block these off.

In conclusion, achieving airtightness is a meticulous process, requiring a blend of the right materials, expert techniques, and regular quality checks. By committing to these practical steps, we bring the theory of airtightness to life, crafting structures that are not only energy-efficient but also resilient against the elements.

Chapter 9: The Crucial Role of Testing in Airtightness

Achieving airtightness is not a matter of mere assumption or theory. It’s a tangible quality, measurable and quantifiable, and this is where testing comes into play. Comprehensive testing serves as a confirmation of our design and construction practices and provides invaluable insights into potential improvements.

9.1 The Essence of Air Testing

- Objective Measurement: Airtightness tests offer a quantitative assessment, translating the efficacy of our strategies into measurable metrics. This allows us to assess if we have met or exceeded the set airtightness standards.

- Timely Detection: By integrating testing at various stages of construction, from the initial phases to the final touches, we can swiftly pinpoint and rectify areas that aren’t meeting the desired standards.

9.2 Techniques and Tools: From Smoke Sticks to Pressure Tests

- Smoke Sticks: A basic yet highly effective technique, smoke sticks or pencils emit visible smoke that gets drawn towards areas of air ingress. This not only visually demonstrates the leakage points but also offers an immediate way to gauge the severity of the issue.

- Blower Door Test: This is a more comprehensive technique, involving the use of a powerful fan to depressurise the building. By measuring the rate at which air flows into the structure to equalise the pressure, this test provides an accurate measure of the building’s overall airtightness.

- Thermal Imaging: Infrared cameras can detect differences in temperature caused by air leakages. This visual method is particularly useful in large structures or in conditions where other methods might be less effective.

9.3 Proactive Addressing of Issues

- Immediate Rectifications: Once a leakage point is detected, immediate steps can be taken to address the issue. This might involve additional sealing, repairs, or even redesigning certain components.

- Iterative Testing: After making necessary modifications, the area or the building can be re-tested to ensure that the remediation has been effective.

9.4 The Broader Impact of Testing

- Ensuring Compliance: Regular testing ensures that our buildings are compliant with the latest regulatory standards, protecting stakeholders from potential legal implications and ensuring the building’s occupants reap the full benefits of an airtight structure.

- Building Confidence: Regular testing instils confidence in both our team and our clients. It demonstrates our commitment to quality, precision, and energy efficiency.

It’s evident that testing is not just a regulatory necessity but an architect’s ally. It offers a clear pathway, turning the abstract concept of airtightness into a concrete achievement. With each test, we come closer to perfecting our understanding of the intricate dance between design, materials, and construction in creating airtight buildings.

Chapter 10: Airtightness Standards: An Overview

Navigating the realm of architectural design and construction without a thorough understanding of prevailing airtightness standards is akin to sailing without a compass. These standards, often instituted by reputed bodies and research organisations, form the foundation for modern sustainable building practices.

10.1 The Evolution of Airtightness Standards

- Historical Context: The recognition of the importance of airtightness is not a recent phenomenon. Over the decades, as our understanding of energy efficiency grew, so did the push for more stringent standards. Initially focused on mere conservation, today’s standards strive for holistic sustainability.

- Current Trends: As technology and construction methodologies advance, so do the benchmarks. Today, the push is not just for airtightness but also ensuring that buildings have effective ventilation, striking a balance between energy conservation and indoor air quality.

10.2 Key Organisations and Their Contributions

- British Standards Institute (BSI): As the national standards body of the UK, the BSI plays a pivotal role in formulating airtightness standards. Their guidelines are comprehensive, covering aspects from material selection to construction techniques, and serve as a reference point for many professionals in the industry.

- Building Research Establishment (BRE): BRE, with its extensive research and consultancy in the built environment, provides invaluable insights and recommendations. Their studies often inform the evolution of standards, ensuring they are rooted in empirical evidence and practical experience.

10.3 Interpreting the Standards: Beyond the Jargon

- Quantitative Benchmarks: Most standards provide specific numerical values that buildings should adhere to. These might pertain to the permissible air leakage rates, insulation levels, or the efficacy of ventilation systems.

- Qualitative Guidelines: Apart from numbers, standards often offer qualitative advice, covering best practices, potential pitfalls, and recommendations for various construction scenarios.

- Case Studies and Examples: Many standards, especially those by research bodies like BRE, also provide real-world case studies. These examples offer a practical perspective, illustrating how the standards translate in real-world scenarios.

10.4 The Global Perspective

- International Standards: While the UK has its unique standards, it’s crucial to be aware of international benchmarks, especially when working on projects with global stakeholders or in different countries. Organisations like the International Organisation for Standardisation (ISO) provide guidelines that often influence or align with national standards.

- Adapting to Local Context: While standards provide a general framework, each building project has its unique context. It’s essential to adapt these guidelines considering local conditions, materials available, and specific project requirements.

In summary, while airtightness standards can initially seem overwhelming, they are invaluable tools in the architect’s arsenal. By staying updated, understanding the rationale behind these standards, and applying them judiciously, architects and builders can ensure that their creations are not just aesthetically pleasing but also environmentally responsible and sustainable.

Conclusion: Airtightness – The Architectural Keystone of Tomorrow

In the vast expanse of architectural elements, airtightness, once perhaps seen as a mere footnote, has steadily grown in stature. The burgeoning focus on sustainability, climate change mitigation, and the inexorable drive for energy efficiency, has placed airtightness at the very heart of contemporary building design and construction.

The Holistic Impact of Airtightness

Airtightness isn’t an isolated discipline; it has a domino effect. Enhanced airtightness in buildings not only conserves energy but also elevates indoor air quality, reduces energy bills, and diminishes the carbon footprint of the structure. It’s a singular solution with multifaceted benefits.

Adapting to a Changing Climate

The global climate crisis mandates swift and effective responses. Buildings, as significant consumers of energy, play a colossal role in either exacerbating or alleviating this crisis. Airtightness is one of the primary solutions within our grasp that can help transform the energy profile of our structures, making them more resilient and less demanding on our planet’s finite resources.

The Cultural Shift in Architectural Design

Beyond the hard metrics of energy savings and carbon reduction, there’s a cultural evolution at play. Homeowners, builders, and stakeholders are increasingly educated about the virtues of airtight design. As this cultural shift continues, architects and designers are in a prime position to lead the narrative, ensuring that airtightness isn’t just a technical specification but a central ethos.

The Road Ahead

There will undoubtedly be challenges. New materials, evolving technologies, and ever-changing regulations will keep the architectural and construction industries on their toes. But with challenge comes opportunity. The commitment to airtightness represents an opportunity to reimagine the buildings of tomorrow, creating structures that are harmonious with their environment, efficient in their function, and exemplary in their design.

In the final analysis, airtightness is more than a technical requisite; it’s a testament to our collective responsibility. It’s about crafting buildings that don’t just stand as monuments to our creativity but as symbols of our commitment to a sustainable future. As we stand on the precipice of architectural evolution, addressing airtightness isn’t just a choice – it’s an imperative for the generations to come.

If you would like to talk through your project with the team, please do get in touch at mail@risedesignstudio.co.uk or give us a call on 020 3290 1003

RISE Design Studio Architects company reg no: 08129708 VAT no: GB158316403 © RISE Design Studio. Trading since 2011.